Subsea trenching is the process of digging a trench in the seabed to bury subsea pipelines, umbilicals and cables. Trenching protects these vital infrastructure assets from damage caused by fishing gear, anchors, and other hazards.

Scroll below to browse through our fleet of trenching equipment and their capabilities.

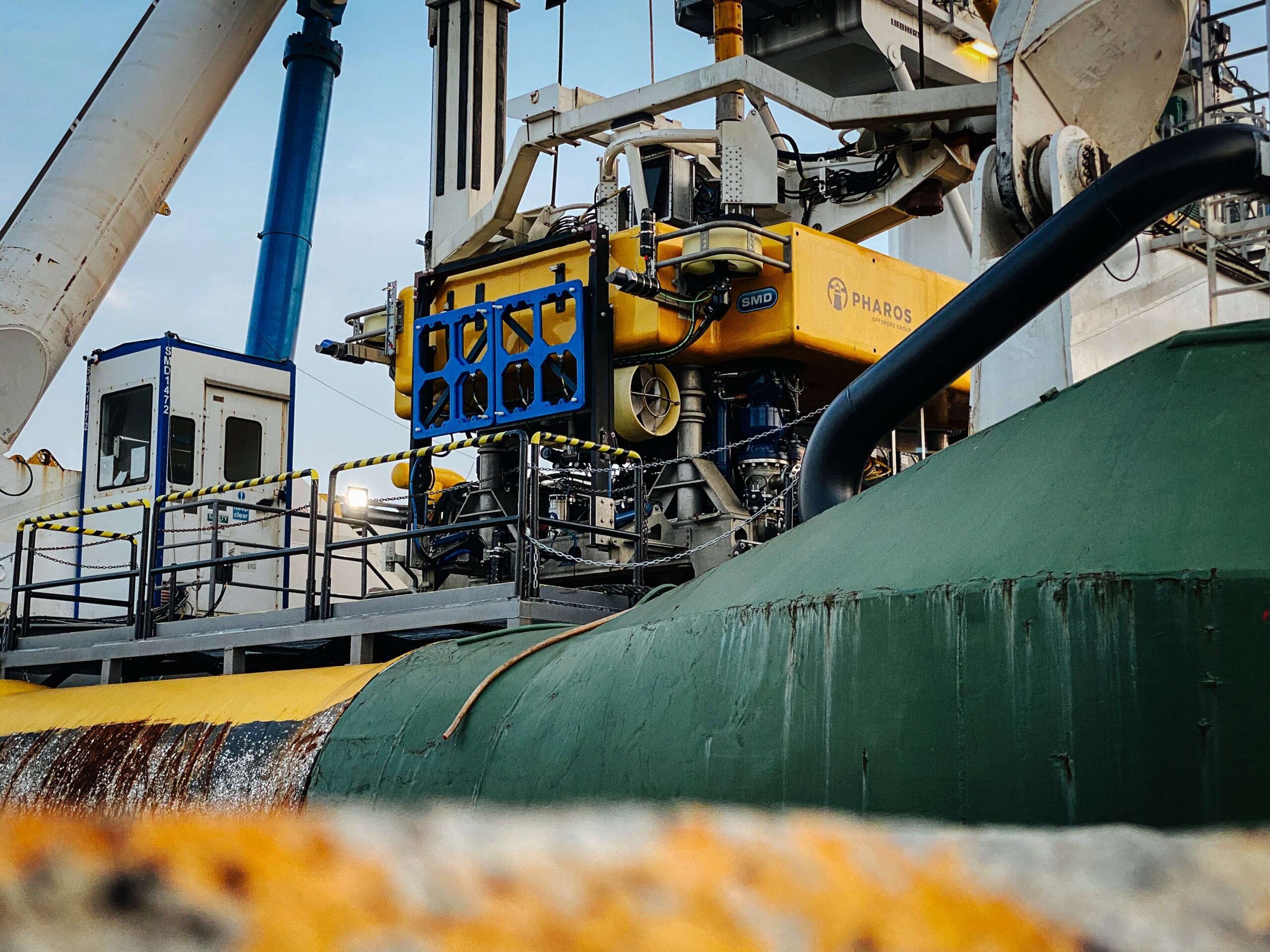

Q1000 TROV is an industry-leading Jet Trenching ROV and embraces the latest technologies in Jet Trenching and ROV design.

UTV1100 TROV is a highly flexible surface fed trenching ROV with a proven burial solution on multiple product types.

UTV400 TROV can undertake all aspects of cable maintenance, seabed survey and cable burial work of long duration, at depths down to 2,500 metres.

3 (+2) x Triton XLS WROV’s are hydraulic heavy-duty Dual Construction and Survey Class ROV’s, designed and built to perform the most exacting operations in the harshest environments.

Work class remotely operated vehicles (WROVs) and observation class remotely operated vehicles (OROVs) are two types of robotic vehicles that are used in the subsea solutions industry.

WROVs are larger and more powerful than OROVs, and they are typically used for more demanding tasks, such as inspection and maintenance of subsea infrastructure. OROVs meanwhile are suited for tasks such as monitoring and surveillance.

1 x Super Mohawk OROV s is robust and durable inspection ROV and is ideal for all inspection and light work tasks.

A wide range of equipment that is used to support subsea operations in a variety of tasks. Some of the most common types of subsea ancillary hire equipment include:

Q1000 TROV is an industry-leading Jet Trenching ROV and embraces the latest technologies in Jet Trenching and ROV design.

UTV1100 TROV is a highly flexible surface fed trenching ROV with a proven burial solution on multiple product types.

UTV400 TROV can undertake all aspects of cable maintenance, seabed survey and cable burial work of long duration, at depths down to 2,500 metres.

CFE500 is based on a hybrid subsea excavation system. The CFE500 has a configurable tilt frame housing allows the base unit to be tilted to 45° from vertical, extending the viable range of the exit flow toward specific targets.

The Mattress Handling Lifting Frame Assembly is built with welded and bolted steel construction and has been tested in accordance with DNV2.7-3. The Mattress Frame has 4 top mounted lifting points and one top bolt on quick connection/ release pin mechanism and 24 underside hang off points.

Industry standard hydraulic five tine rock grab can be utilised with an ROV for assistance or with ancillary sensors for independent operation. The grab can be coupled with an ROV hot stab for deep water applications.

As standard the hydraulic cable grab is fitted with a certified lift point suitable for recovery and deployment, this is to be attached to a suitable crane or winch wire. The grab is supplied hydraulic pressure from the surface and actuated by means of the integral hydraulic cylinder.

Click Below for the spec sheet which allows for a load of 8Te to be successfully lifted.

VIEW SPEC SHEET

Click below for the spec sheet which allows for a load of 10Te to be successfully lifted.

VIEW SPEC SHEET

The Hydraulic Cable Cutter is a marinized shear suitable for multiple offshore operations. Capable of shearing solid metal bars, cables, heavy schedule pipe or concrete coated pipelines. The system can be operated topside or via hot stabs.